Check weighers: Ensuring accurate food packaging weights

Check weighers are ensuring accurate food packaging weights. These machines automatically check the weight of packaged foods. They are used in the food packaging industry to ensure that the weight of a package is within specified limits. This quality control check helps to meet legislative requirements and also provides customer satisfaction.

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Check weighers: Ensuring accurate food packaging weights

Check weighers are machines that automatically check the weight of packaged foods. They are used in the food packaging industry to ensure that the weight of a package is within specified limits. This quality control check helps to meet legislative requirements and also provides customer satisfaction.

Check weighers work by weighing each package as it passes over a conveyor belt. The weight is measured using load cells, which are sensitive devices that convert weight into an electrical signal. The electrical signal is then processed by a computer, which determines whether the package weight is within the specified limits.

If a package’s weight is outside the specified limits, the check weigher will reject the package. This can be done by ejecting the package from the conveyor belt, or by diverting the package to a different area for further inspection.

Check weighers are used in a variety of food packaging applications, including:

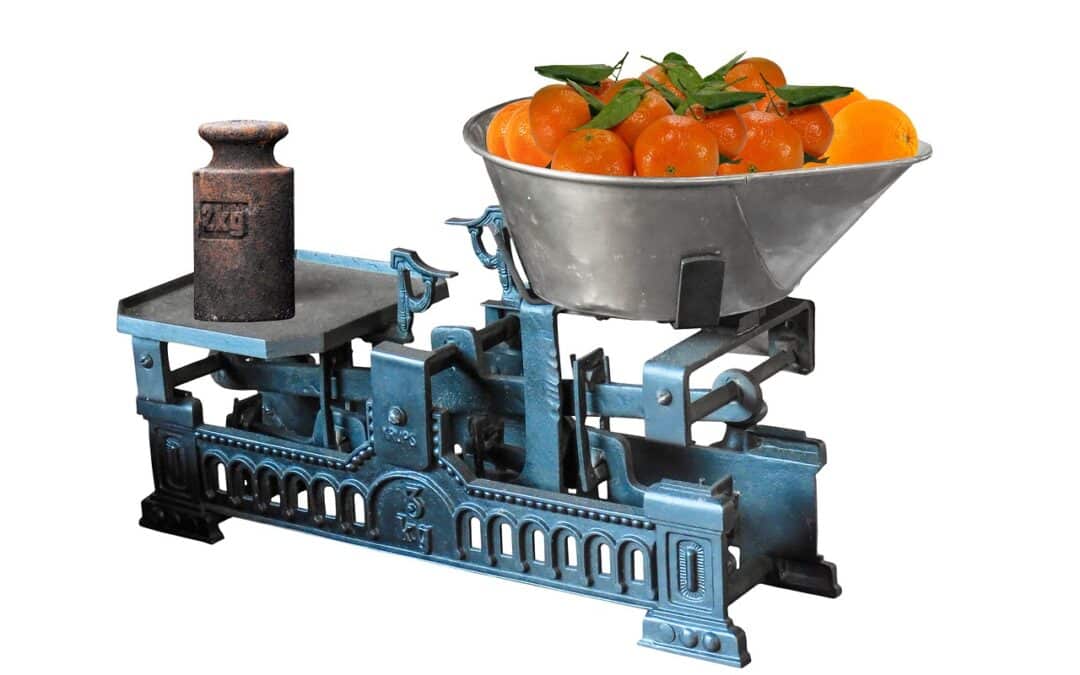

- Weighing fresh produce, such as fruits and vegetables

- Weighing packaged meats and cheeses

- Weighing frozen foods

- Weighing baked goods

- Weighing snack foods

Check weighers are an essential tool for food packaging companies that want to ensure that their products meet the highest quality standards. Also when Ensuring Accurate Food Packaging Weights

Benefits of using check weighers

There are many benefits to using check weighers in the food packaging industry. These benefits include:

- Reduced waste: Check weighers can help to reduce waste by identifying and rejecting underweight or overweight packages. This can save food companies a significant amount of money in the long run.

- Improved product quality: Check weighers can help to improve product quality by ensuring that each package contains the correct amount of product. This helps to meet customer expectations and build trust in the brand.

- Compliance: Check weighers can help food companies to comply with government regulations on food packaging weights.

- Increased efficiency: Check weighers can help to increase the efficiency of the food packaging process by automating the weight-checking process. This also frees up workers to focus on other tasks.

How to choose the right check weigher

There are several factors to consider when choosing a check weigher, including:

- The type of food product being packaged

- Also, the required weighing accuracy

- The production line speed

- Lastly, the budget

It is important to choose a check weigher that is designed for the specific needs of the food packaging company.

Conclusion of Ensuring accurate food packaging weights

Check weighers are an essential tool for food packaging companies that want to ensure that their products meet the highest quality standards. Also, check weighers can help to reduce waste, improve product quality, comply with regulations, and increase efficiency.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.