Packaging Verification Systems

-

High-Mark Systems: Ensure Accurate Packaging Every Time

Simple, reliable solutions for verifying packaging and part marking.

- 100% product inspection: Eliminate mispackaging, especially crucial for allergens.

- Automatic rejection: Wrong package? System stops production for removal.

- Real-time event recording: Track & review all occurrences with image capture.

- Enhanced security: Employee badge scan for access and accountability.

- Maximize efficiency: Minimized downtime and labor costs with seamless conveyors and sorters.

- Reduce costs: Automate tasks, simplify maintenance.

Custom-designed systems for your specific needs.

High-Mark Systems builds automated solutions tailored to your product, packaging, and speed requirements. Conveyors, sorters, and other components work together seamlessly for optimal efficiency and reduced costs. Also compatible with multiple symbologies including invisible code.

-

Key benefits:

- Accuracy: Eliminate mispackaging and ensure product safety.

- Efficiency: Maximize production uptime and reduce labor costs.

- Security: Track and control access for accountability.

- Customization: Get a system that perfectly fits your needs.

Contact High-Mark Systems today for a packaging verification solution that meets your business goals.

Service, Service and

More Service!

Our team is committed to providing responsive and knowledgeable service. We stand behind and support all our products to meet and exceed our customers’ needs.

We pride ourselves on our high customer retention and strong relationships.

Come By and See Us Today!

High-Mark Systems

8823 Zealand Avenue North Suite K

Minneapolis, MN 55445

Packaging Verification Systems

High-Mark 9900 Series

The affordable high-performer

The 9900 series is a packaging verification system engineered for rapid bar code scanning. With it being our model designed for the highest inspection speed at up to 1400 inspections a minute, the 9900 series will be able to accomplish any tasks in record time. Additionally, The 9900 series offers a 3.5″ LCD touch display, and with its easy to use interface, the High-Mark bar code scanner can be easily integrated into any production environment no matter how extreme.

High-Mark Data Pro 2

The industrial high-performer

The High-Mark Systems Data Pro 2 is a system designed to interface with and collect data from up to two verification devices such as barcode scanners, machine vision cameras, or other sensors. When the Data Pro 2 detects a product on the production line it sends a trigger to one or both of the inspection devices. Based on the data provided by the inspection devices the system will then decide that the product is either known good, unknown, or bad. The unknown and bad products can be removed from the line automatically with one of the optional reject mechanisms or manually after the system stops the production line. The Data Pro 2 stores the information received from the inspection devices so that production trends can later be analyzed. Also, provides full production reports of each triggered event with the ability to save images related to triggered events.

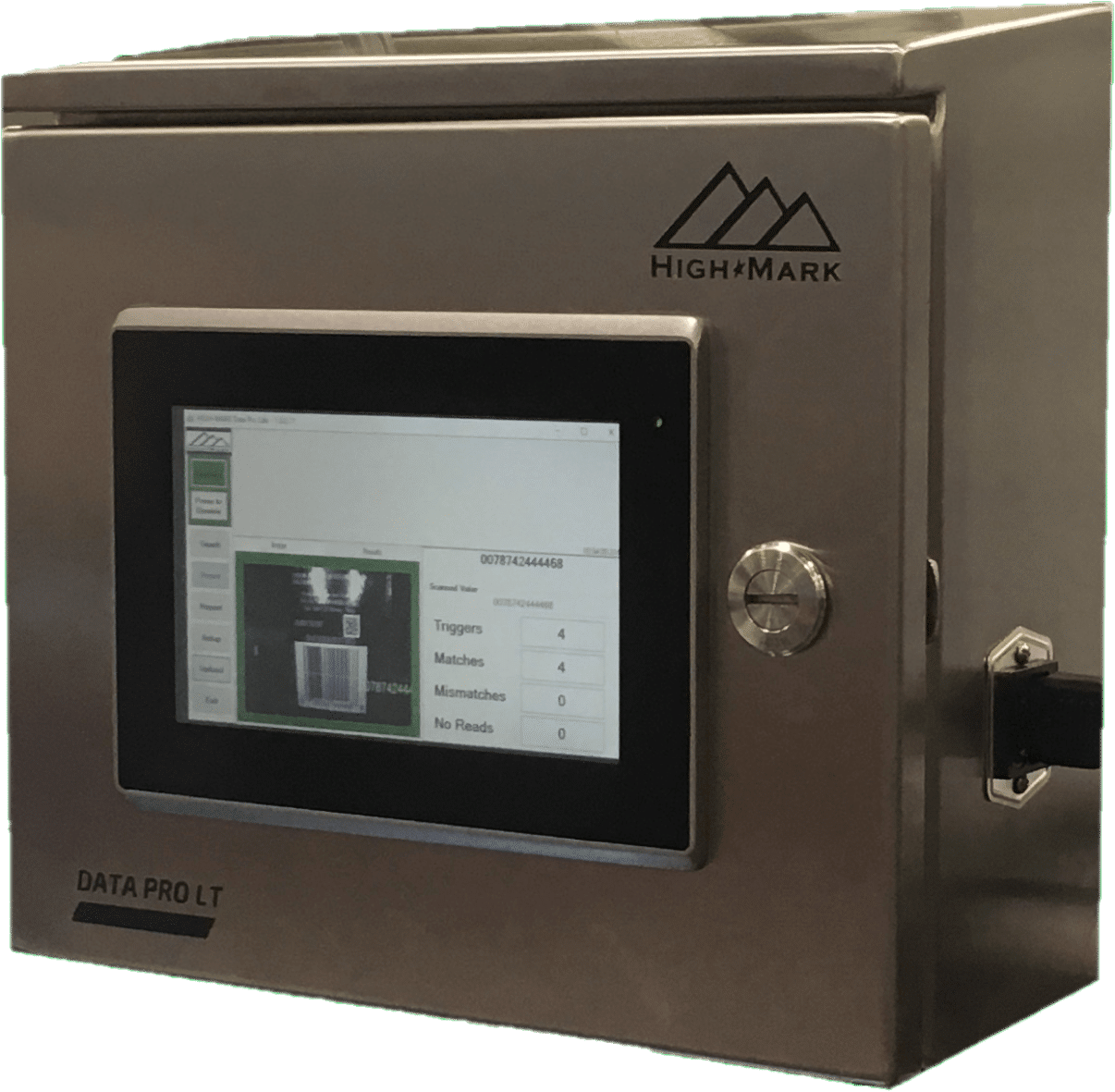

High-Mark Data Pro Lite

Fully featured for a single camera auto ID interface

The High-Mark Data Pro Lite is a advanced packaging verification system designed for user experience and customizability. With its 7″ camera image display, users can see exactly how and where the data is being captured, allowing for precise information management. With positive data detection per trigger, the Data Pro LT can detect faulty scanners, generate alerts, and make sure not even a single scan is ever missed on the product line.

High-Mark Data Pro 6

Multi-Camera Industrial High Performer