Automatic Material Handling Systems

-

The Best Automated Material Handling Systems

Automated Material Handling Systems: The Best Way to Maximize Efficiency and Reduce Costs

Automated material handling systems (AMHS) are an essential part of many modern businesses. They can be used to improve efficiency and accuracy in a wide range of industries. Especially in manufacturing and warehousing to e-commerce and healthcare.

AMHS uses a variety of technologies to move materials from one point to another without human intervention. This can include conveyors, sorters, robots, and autonomous vehicles. Additionally, AMHS can also be custom-designed to meet the specific needs of a business. Furthermore, they can be scaled up or down as needed.

Benefits of Automated Material Handling Systems

AMHS offers a number of benefits to businesses of all sizes, including:

-

Increased efficiency:

AMHS can move materials much faster and more efficiently than humans can. Hence, this can lead to significant reductions in production time and costs.

-

Improved accuracy:

AMHS is also very accurate at moving materials. This can help to reduce errors and improve product quality.

-

Reduced labor costs:

AMHS can also automate many tasks that are currently performed by human workers. This can free up workers to focus on more value-added activities.

-

Improved safety:

Furthermore, AMHS can also help to reduce the risk of workplace accidents. Comparatively, AMHS can be used to move heavy or hazardous materials without the need for human workers to handle them.

Contact High-Mark Systems today for a packaging verification solution that meets your business goals.

-

Long-term Experience

You Can Trust

High-Mark has more than 40 years of experience in the Automatic Material Handling Systems industry. We have provided solutions and service to customer all across North America. Find out how we can help you too.

Schedule a tour or set up a consultation today!

763-428-9950

Call Us for a Free Consultation!

763-428-9950

Choose the best in the business for your business. Contact us today for more information on what we can do for you!

Automated Material Handling

Hugger Belt System

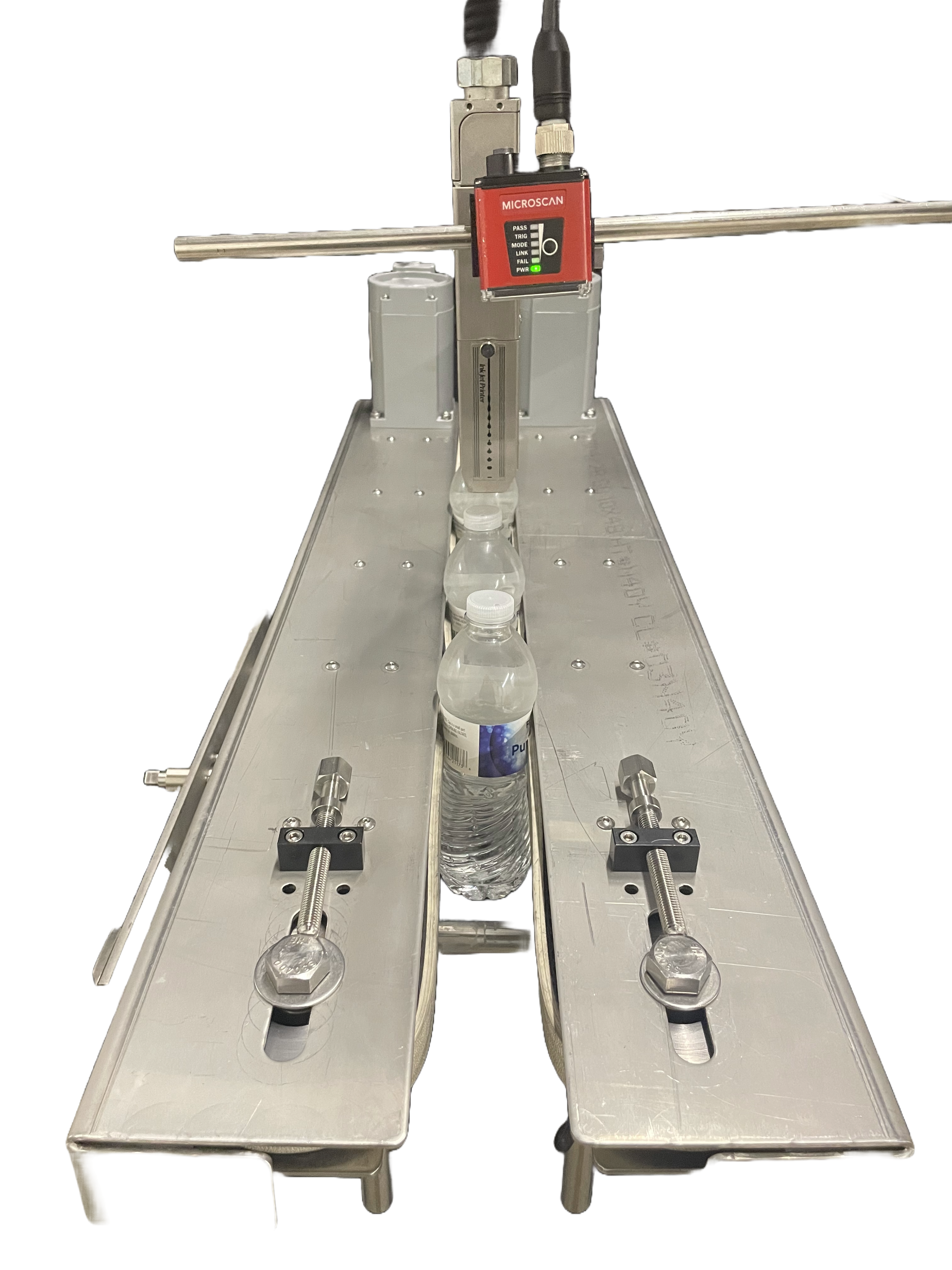

Bottomless Side Belt Transfer Conveyor

A Bottomless Side Belt Transfer Conveyor is a specialized conveyor system designed to efficiently move containers along a production line while providing unobstructed access to the bottom of the items. Unlike traditional belt conveyors that have a solid base, this conveyor utilizes two gripping side belts that hold the containers securely. This allows for tasks like printing, labeling, or inspecting the underside of the product to be completed efficiently without needing to transfer it to another machine.

These conveyors are ideal for various applications in the packaging industry. They are particularly useful for tasks such as coding expiration dates or lot numbers on the bottom of bottles and cans. Additionally, they can be used for products that might be unstable on a traditional conveyor belt, ensuring they are moved safely and securely throughout the production line.

Eastey SB-2EX

Random Side Belt Case Taper

Eastey’s SB-2EX Random allows users to run a variety of case sizes without having to manually adjust for each box. The system’s unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

The SB-2EX Random’s side belts are great for heavy weight, narrow, or small boxes. It is ideal for void-fill random cases where the packaged product does not support the box. SB-2EX Random is designed to handle boxes that most other case tapers can’t.

Eastey VCTS

Vertical Case Transport System

Eastey’s Vertical Case Transport System allows users to print on two or four adjacent sides of a case eliminating the need for pre- printed cases or expensive labeling equipment and supplies. Adjustable width settings on our standard VCTS allow users to print on cases ranging in size from 10” x 10” up to 33” x 29”. A larger VCTS -XL allows cases from 21” x 10” up to 48” x 29”.

Eliminate the high costs associated with pre-printed cases

by printing product specific information directly onto blank cases. Any way you look at it, Eastey’s VCTS provides users with an affordable solution to meet your case printing needs. Proven reliability. Simple operation.

Eastey ERX-15

ERX-15 Automatic Case Erector

The ERX-15 Case Erector from Eastey is designed to automatically erect and seal the bottom of your cases at production rates up to 15 cases per minute. The ERX 15 is designed to keep production and maintenance efforts at a minimum while providing fast, efficient case erecting, making the ERX-15 an ideal alternative to manual case forming.

The ERX-15 Case Erector enables a single operator to form, seal, and pack corrugate cases. Operation is simple: load up to 200 cases in the case magazine hopper and set your operation to run or jog mode. Separators release the leading blank case where a series of eight vacuum suction cups hold the case in a properly formed square position. After a set of stationary flap folding bars fold both minor and major bottom flaps, the case is then transitioned and the bottom is sealed with Eastey’s proven EX tape head.

Eastey SB-2EX-SS

SB-2EX-SS Stainless Steel Side Belt Case Taper

Eastey’s SB-2EX-SS Case Taper offers the quality that you have come to rely on from Eastey. The system’s unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

The SB-2EX-SS’s side belts are great for light or heavy weight, narrow or small boxes. It is ideal for void-fill cases where the packaged product does not support the box.

Eastey Easy Packer

Easy Packer Side Belt Case Taping System

The side belt-driven Easy Packer is designed for compact, packing and sealing. The durable design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum. The Easy Packer provides a fast and cost-efficient alternative to hand taping.

Designed with the customer in mind, the Easy Packer is supplied with extended side rails, flap closing bars, and a 48” anvil packing station (not shown) to assist with the packing and sealing process. Operation is simple: open the case, manually fold the bottom front and back minor flaps, and place the case on the anvil to be filled. Once filled, the operator pushes down and holds the top trailing minor flap while the box enters the machine to be sealed.