Bottom Coding With The Hugger Belt Conveyor. Ever wondered how those expiration dates or batch codes magically appear on the bottom of your favorite products?

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Bottom Coding With The Hugger Belt Conveyor

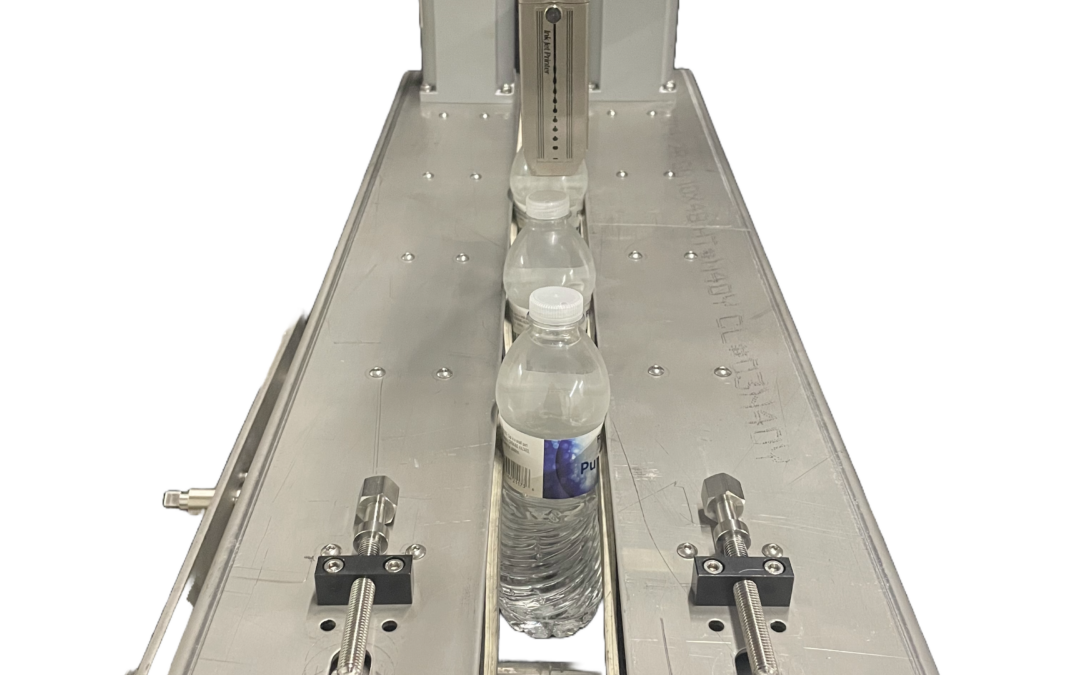

Ever wondered how those expiration dates or batch codes magically appear on the bottom of your favorite products? It’s not magic, but a clever piece of equipment called the Hugger Belt Conveyor. This unsung hero of the production line plays a crucial role in ensuring clear and accurate coding on the underside of containers.

Decoding the Bottom Line

Traditional conveyor belts can be a real roadblock (pun intended) when it comes to bottom coding. Their flat surface obscures the very area that needs the code. This is where the Hugger Belt steps in. Its ingenious design features side grips that hold the container securely, but leave the all-important underside completely exposed.

Picture this: Your product travels along the Hugger Belt, cradled by the side grips. As it glides past a strategically placed coding unit, the exposed bottom receives a crisp and precise application of the date code or lot number. This seamless integration ensures consistent and reliable coding, every single time.

More Than Just a Pretty Code

Hugger Belt Conveyors offer additional benefits beyond bottom coding:

- Versatility: They can handle a wide range of container shapes and sizes, making them adaptable to various production lines.

- Efficiency: The exposed bottom allows for faster and more efficient coding compared to alternative methods.

- Gentleness: The side grips provide a secure hold without damaging delicate products.

- Cleanliness: Many Hugger Belts are constructed with sanitary stainless steel, ideal for applications in the food and beverage industry.

Keeping Your Codes Clear and Your Production Line Running

So, next time you pick up a product and see that all-important code on the bottom, remember the Hugger Belt Conveyor. It’s the hidden hero quietly ensuring clear, accurate, and efficient coding for a smooth-running production line.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.