Checkweighers: The Key to Quality and Compliance in Your Production Process

How are checkweighers the key to Key to Quality and Compliance in Your Production in your production process?

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and also our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Checkweighers: The Key to Quality and Compliance in Your Production Process

How are checkweighers the key to Key to Quality and Compliance in Your Production in your production process?

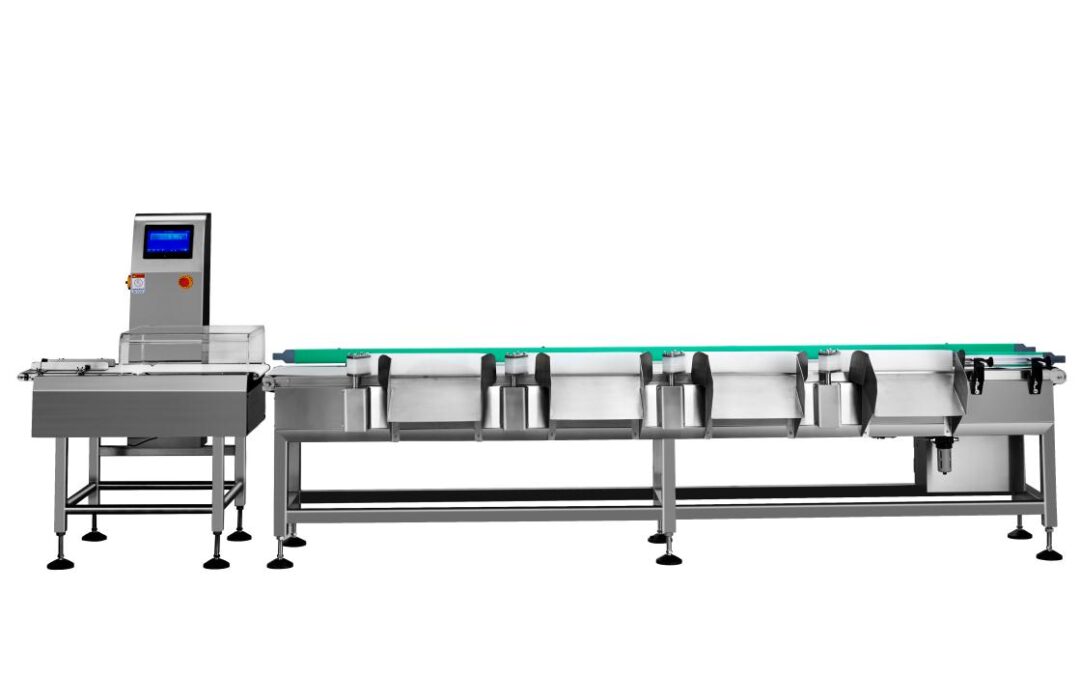

Checkweighers are essential tools for ensuring quality and compliance in a variety of production processes. They are used in weighing products as they move along a conveyor belt and also reject any items that are underweight or overweight. This helps to prevent product recalls and also other costly problems.

Why are checkweighers important?

Checkweighers are important for a few reasons:

- Quality control: By ensuring that products meet the correct weight requirements, checkweighers help to improve product quality. This is especially important for food and beverage products, pharmaceuticals, and also other products where product weight can have a significant impact on quality.

- Compliance: Many industries have regulations that require products to meet certain weight requirements. Checkweighers help businesses to comply with these regulations and also avoid costly fines or penalties.

- Consumer protection: Checkweighers help to protect consumers from being cheated. For example, if a food product is underfilled, consumers are getting less of the product than they paid for.

How do checkweighers work?

Checkweighers use a variety of technologies to weigh products accurately. The most common type of checkweigher uses load cells to measure the weight of the product. Load cells are sensors that convert force into an electrical signal. The electrical signal is then sent to a computer, which calculates the weight of the product.

How can we help?

Contact us to find out how our diverse products, services and also solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.