Packaging Verification and Checkweighing: A Dynamic Duo for Food Safety

In the fast-paced world of food manufacturing, ensuring product quality and safety is paramount. Two essential tools in the arsenal of quality control are packaging verification and checkweighing.

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Packaging Verification and Checkweighing: A Dynamic Duo for Food Safety

In the fast-paced world of food manufacturing, ensuring product quality and safety is paramount. Two essential tools in the arsenal of quality control are packaging verification systems and checkweighers. When working in tandem, these technologies form a robust defense against product defects and consumer dissatisfaction.

Understanding the Roles

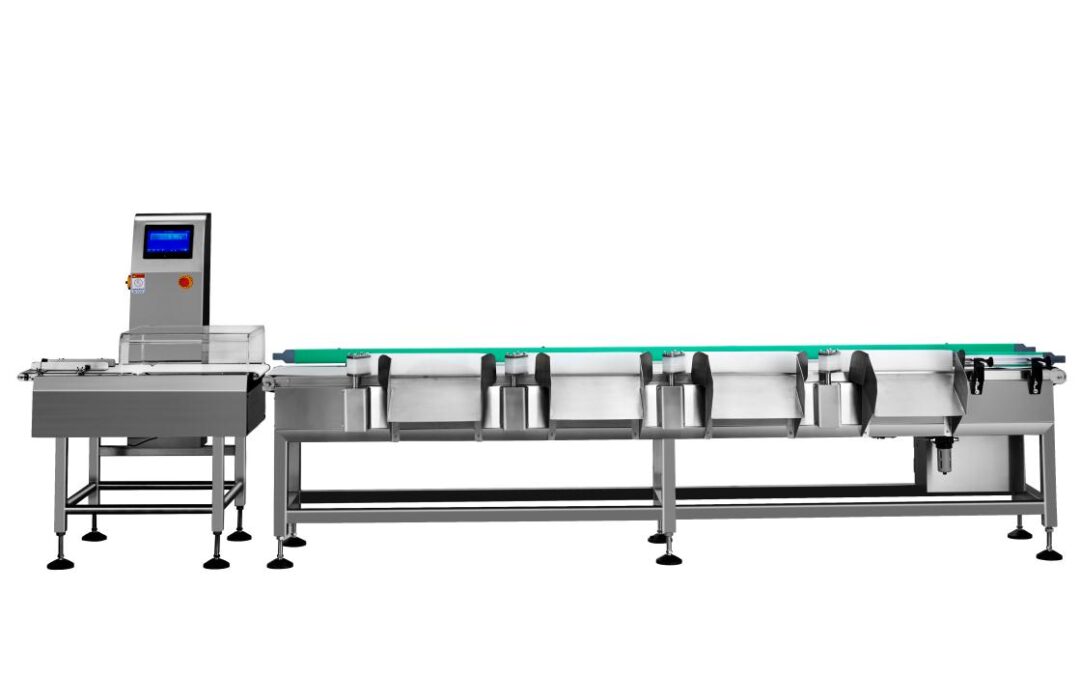

- Checkweigher: This machine accurately measures the weight of packaged products as they move along the production line. It compares the actual weight to pre-set parameters and rejects any items that fall outside the specified range. This helps to prevent underfilling, overfilling, and inconsistencies in product weight.

- Packaging Verification System: This system goes beyond weight to inspect the overall integrity of the package. It verifies critical packaging attributes such as seal integrity, label placement, and correct product presence. It can also detect contaminants or foreign objects that may have inadvertently entered the package.

How They Work Together

The combination of a checkweigher and packaging verification system creates a comprehensive quality control checkpoint. Here’s how they complement each other:

- Initial Weight Verification: The checkweigher is typically the first line of defense. It quickly assesses the weight of each package and removes underfilled or overfilled products from the line.

- Comprehensive Package Inspection: Products that pass the weight check then move to the packaging verification system for a more in-depth examination. This system scrutinizes the package for any defects or contaminants.

- Data Integration: Modern systems often integrate data from both machines. This allows for detailed analysis of production trends, identifying potential issues before they become significant problems.

- Continuous Improvement: By monitoring the performance of both systems, manufacturers can fine-tune production processes, reduce waste, and enhance overall efficiency.

Benefits of the Partnership

- Enhanced Product Quality: By detecting and removing defective products, these systems help to maintain consistent product quality and customer satisfaction.

- Reduced Costs: Preventing product recalls and minimizing waste can lead to significant cost savings.

- Improved Brand Reputation: Consumers trust brands that prioritize safety and quality.

- Compliance with Regulations: Many food safety regulations require specific quality control measures. These systems help ensure compliance.

- Increased Efficiency: By identifying and addressing issues promptly, production efficiency can be improved.

In conclusion, the combination of packaging verification systems and checkweighers is essential for modern food manufacturing. By working together, these technologies create a powerful barrier against product defects and ensure that only the highest quality products reach consumers.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.