Keeping it Smooth: How Hugger Belt Conveyors are Saving the Day (and the Bottles)

How are Hugger Belt Conveyors Saving the Day? In the fast-paced world of manufacturing, efficiency is king. Every second counts and any hiccup in the production line can lead to delays and lost profits.

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Keeping it Smooth: How Hugger Belt Conveyors are Saving the Day (and the Bottles)

In the fast-paced world of manufacturing, efficiency is king. Every second counts, and any hiccup in the production line can lead to delays and lost profits. One area that can be particularly prone to disruption is the transfer of bottles and other containers between conveyors.

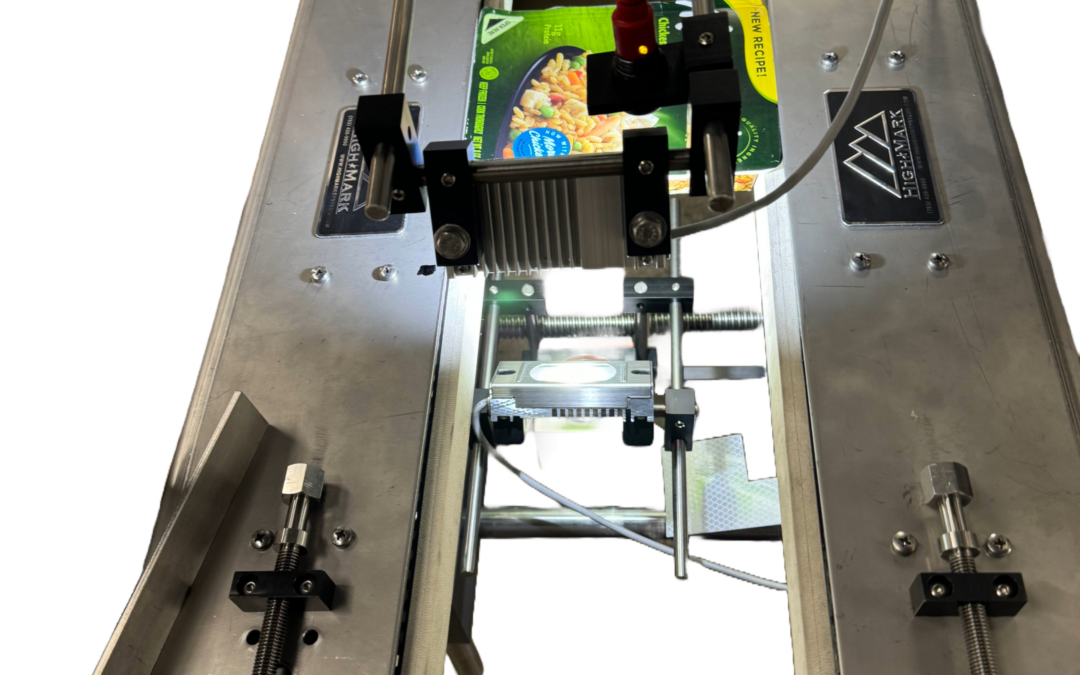

Enter the Hugger Belt Bottle Transfer Conveyor, a conveyor system designed to streamline this critical process.

Here’s how Hugger Belts are making waves in the industry:

- Flawless Bottom Coding: Imagine printing an expiration date or batch number on a bottle. Traditional conveyors can make this tricky, as the belt itself gets in the way. Hugger Belts solve this problem with their unique design. They feature side grips that hold the container securely, leaving the bottom completely exposed. This allows for perfect placement and clear printing of essential codes directly onto the base of the bottle.

- Seamless Transfers, No Tipping Allowed: Moving bottles from one conveyor to another can be risky business. Traditional methods often rely on “dead plates” – flat surfaces that bridge the gap between conveyors. However, these dead plates can cause bottles to tip over and jam the system. Hugger Belts eliminate this hazard entirely. Their side grips ensure a smooth, stable transfer, keeping your bottles upright and your production line flowing.

Beyond the Basics:

Hugger Belts offer several additional advantages:

- Versatility is Key: They can handle a wide variety of bottle shapes and sizes, making them a true all-rounder in the production line.

- Easy Cleaning Makes a Difference: Many Hugger Belts are constructed with sanitary materials like stainless steel. This allows for easy cleaning and disinfection, crucial for maintaining hygiene standards in food and beverage applications.

- Adapting to the Flow: Hugger Belts come with adjustable speed controls. This means you can fine-tune the belt’s movement to perfectly match the specific requirements of your production line.

So, next time you see a smoothly running conveyor system handling bottles or other containers, remember the Hugger Belt lurking beneath the surface. It’s a testament to innovative design that keeps things moving efficiently, one bottle at a time.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.