The Secret Weapon of Bottom Coding: The Hugger Belt Conveyor

Have you ever wondered how those expiration dates or batch codes get magically printed on the bottom of your favorite beverage can? It’s not magic, but a clever invention, The Secret Weapon of Bottom Coding, called the Hugger Belt Conveyor.

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

The Secret Weapon of Bottom Coding: The Hugger Belt Conveyor

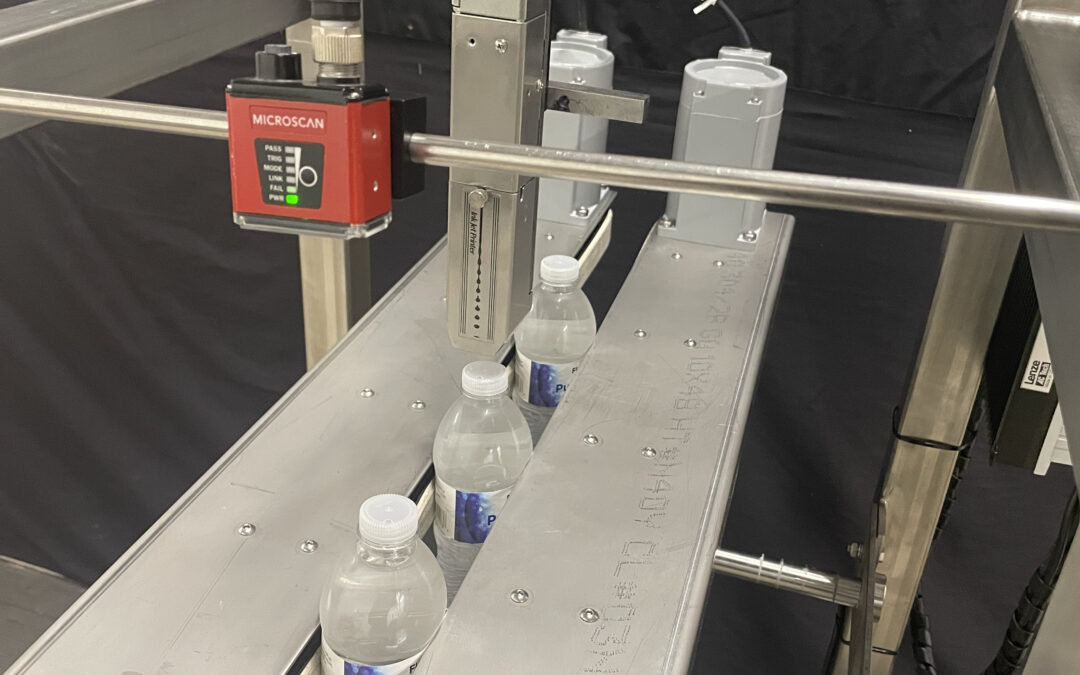

Have you ever wondered how those expiration dates or batch codes get magically printed on the bottom of your favorite beverage can? It’s not magic, but a clever invention called the Hugger Belt Conveyor. This unsung hero of the production line plays a vital role in ensuring your products are clearly coded and ready to hit the shelves.

Decoding the Bottom Code Challenge

Printing codes on the bottom of a container can be tricky. Traditional conveyor belts block access to this crucial area. This is where the Hugger Belt steps up. Unlike its flat counterparts, the Hugger Belt features special side grips. These grips hold the container securely from the sides, also leaving the underside completely exposed. This creates a perfect platform for a coding unit, such as an inkjet coder, to apply clear and precise codes directly onto the bottom of the product as it glides along the conveyor.

Beyond Bottom Coding: A Grip on Efficiency

Hugger Belt Conveyors offer more than just a solution for bottom coding. Here’s how they can benefit your production line:

- Smooth Sailing: Hugger Belts eliminate the need for manual product handling during transfers, promoting a smooth and also efficient flow.

- Versatility: These grippy wonders can handle a wide range of container shapes and also sizes, making them a multi-purpose asset.

- Gentle Touch: The side grips provide a secure hold without damaging delicate products.

- Cleanliness: Many Hugger Belts are constructed with sanitary stainless steel, ideal for food and beverage applications where hygiene is paramount.

Keeping Your Codes Clear and Your Production Line Running

So, the next time you pick up a coded product, remember the silent hero behind it – the Hugger Belt Conveyor. It’s the secret weapon ensuring your products are clearly coded, efficiently transferred, and ready to reach their destination. By creating a stable platform for bottom coding and promoting smooth product flow, Hugger Belts are a valuable addition to any production line.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.