Hugger Belts: The Unsung Heroes of the Conveyor Belt World

While the world of conveyor belts might not be the most glamorous, there’s a hidden hero behind the scenes: the hugger belt. These unsung devices play a vital role in keeping manufacturing lines running smoothly. They really are The Unsung Heroes of the Conveyor Belt World.

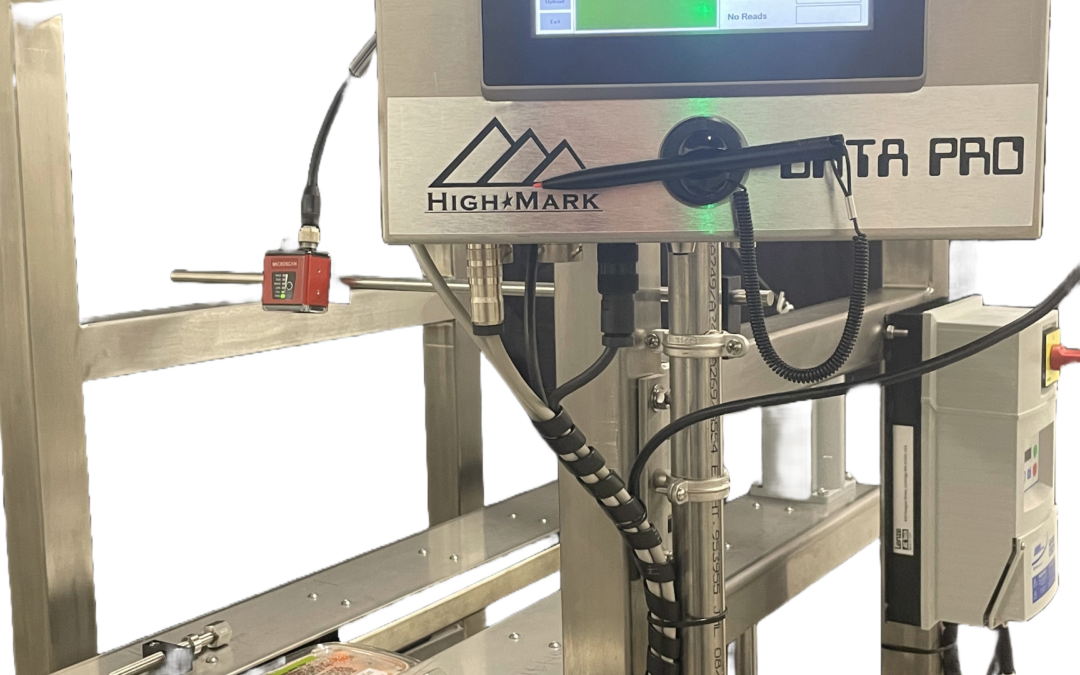

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Hugger Belts: The Unsung Heroes of the Conveyor Belt World

While the world of conveyor belts might not be the most glamorous, there’s a hidden hero behind the scenes: the hugger belt. These unsung devices play a vital role in keeping manufacturing lines running smoothly.

What are Hugger Belts?

Unlike your standard conveyor belt, hugger belts don’t have a solid surface. Instead, they utilize two side grips that hug the sides of containers. This unique design offers several advantages:

- Bottom-up Coding: Ever wondered how those expiration dates and batch numbers get printed on the bottom of containers? Hugger belts come to the rescue! By exposing the container’s base, they allow for direct access for printing equipment like continuous inkjet (CIJ) systems.

- Gentle Transfers: Moving containers between conveyors can be tricky. Standard belts risk damaging delicate items. Hugger belts provide a secure and gentle grip, ensuring your products move safely from one stage of production to the next.

Applications of Hugger Belts:

Hugger belts find use in a wide range of industries, including:

- Food and Beverage: Printing production codes on bottles, cans, and other containers.

- Pharmaceuticals: Ensuring safe and precise handling of medication vials and equipment.

- Cosmetics: Maintaining the integrity of product packaging during transfers.

The Benefits of Hugger Belts:

Here’s a quick rundown of why hugger belts are a great choice for your manufacturing line:

- Versatility: They can handle a variety of container shapes and sizes.

- Efficiency: They facilitate faster and more efficient product coding.

- Product Protection: Their gentle grip minimizes the risk of damage during transfers.

Conclusion of The Unsung Heroes of the Conveyor Belt World :

Next time you see a neatly coded product on a store shelf, remember the silent hero behind it: the hugger belt. These workhorses of the conveyor belt world keep production lines running smoothly and efficiently, ensuring you get your favorite products in pristine condition.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.