Hugger Belts: The Gentle Giants of Conveyor Systems. Have you ever wondered how those perfectly labeled bottles and cans end up on store shelves?

We can help with Industrial Marking and Identification Systems information!

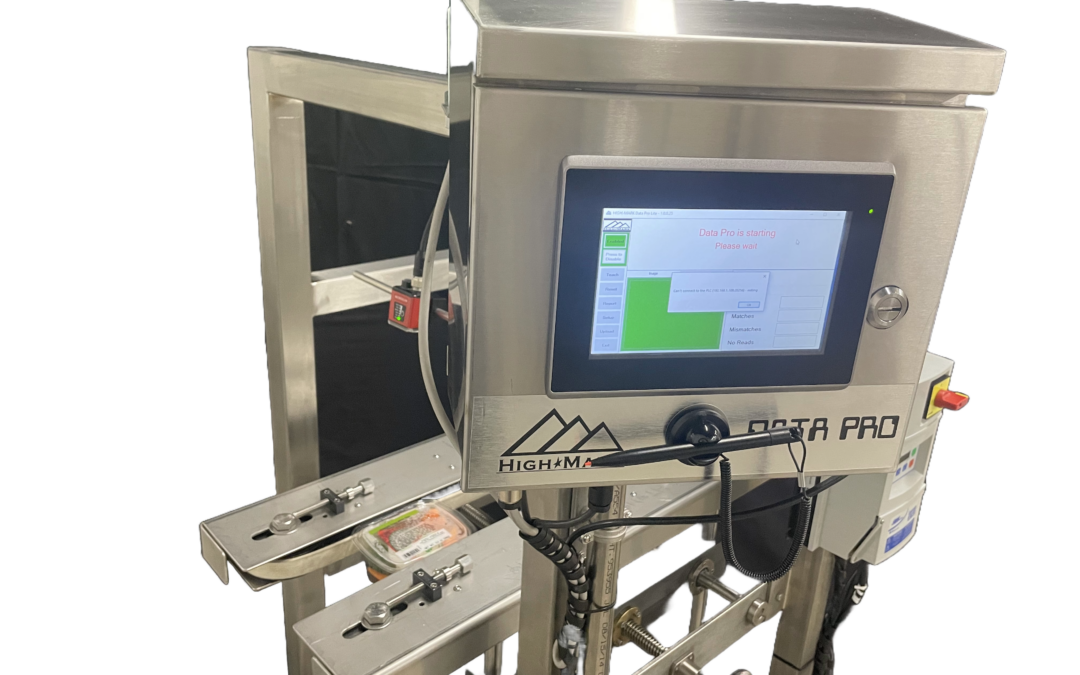

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Hugger Belts: The Gentle Giants of Conveyor Systems

Have you ever wondered how those perfectly labeled bottles and cans end up on store shelves? A key player behind the scenes is the unsung hero of the bottling world: the hugger belt.

Hugger belts are specialized conveyor belts designed to gently grip the sides of containers, most commonly bottles, jars, and tubs. Their unique feature? An open underside that allows for unobstructed access to the container’s base. This seemingly simple design unlocks a surprising range of functionality on the production line.

1. Bottom-Up Coding:

Ever flipped a juice carton to find the expiration date? Hugger belts play a critical role in applying these essential markings. The open underside allows for a continuous inkjet (CIJ) coding system to be positioned directly below the conveyor. As the container travels along the belt, the CIJ system precisely stamps the bottom with the necessary codes, ensuring clear and consistent labeling.

2. Conveyor Transfer Champions:

Imagine a production line with multiple conveyor belts working in tandem. Hugger belts excel at transferring products between conveyors. Their gentle gripping action secures containers during the transfer process, preventing tipping or damage. This smooth transition keeps the line running efficiently and minimizes product loss.

3. Versatility Reigns Supreme:

While commonly used in the food and beverage industry, hugger belts are adaptable to various applications. Their gentle handling makes them suitable for delicate items or those with uneven bases. Additionally, the open base allows for easy integration with other equipment, such as inspection systems.

Hugger belts may not be the most glamorous equipment on the production line, but their contribution is undeniable. They ensure efficient and precise product handling, ultimately helping to deliver those perfectly labeled goods we rely on every day.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.