Choosing the Right Checkweigher for Your Needs

How do you choose the right checkweigher for your needs In the fast-paced world of food production, precision and efficiency are paramount. Every step from ingredient preparation to packaging plays a crucial role in ensuring product quality and consistency. Checkweighers, unsung heroes of the production line, silently safeguard these standards by verifying the weight of each product.

We can help with Industrial Marking and Identification Systems information!

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

Choosing the Right Checkweigher for Your Needs

In the fast-paced world of food production, precision and efficiency are paramount. Every step from ingredient preparation to packaging plays a crucial role in ensuring product quality and consistency. Checkweighers, unsung heroes of the production line, silently safeguard these standards by verifying the weight of each product.

The Right Checkweigher for Your Needs

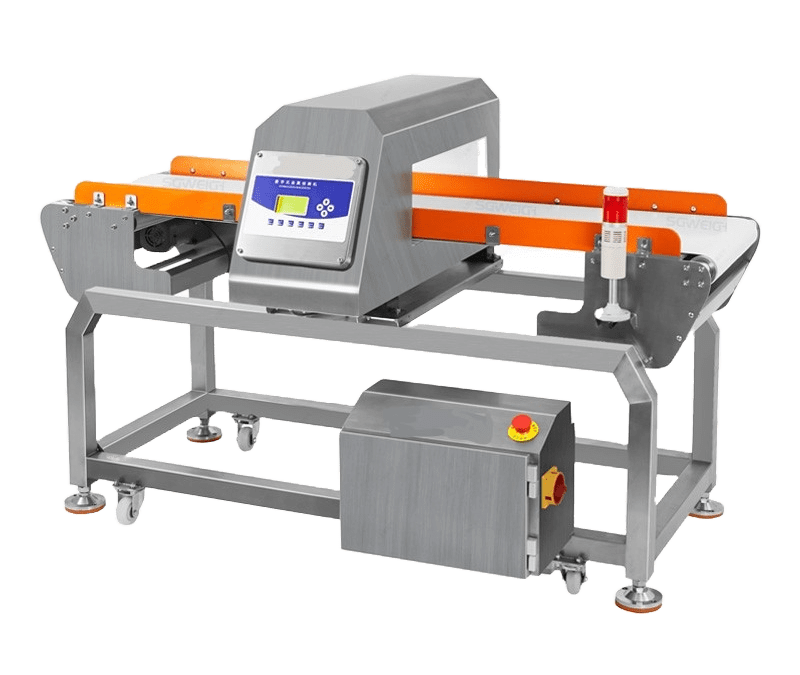

With a plethora of checkweighers available, selecting the perfect fit for your production line requires careful consideration. Factors such as product type, production speed, and budget play a significant role in this decision.

- Product Type: Checkweighers come in various configurations to accommodate different product types. For wet or messy products, waterproof checkweighers are essential. If your production involves a wide range of product sizes, consider a checkweigher with adjustable conveyors and transfer mechanisms.

- Production Speed: If speed is a priority, opt for a checkweigher that can handle your production volume without compromising accuracy. High-speed checkweighers can process hundreds of products per minute, ensuring seamless integration into your production line.

- Budget: Checkweighers range in price depending on their features and capabilities. Define your budget upfront and explore options that align with your requirements without breaking the bank.

Key Features and Benefits of Checkweighers

Checkweighers offer a range of features that enhance production efficiency and product quality:

- Touch Screens: Intuitive touch screens simplify operation and provide real-time data access.

- Responsive Load Cells: Accurate load cells ensure precise weight measurements, minimizing underweight or overweight products.

- Error Alerts: Proactive error alerts flag potential issues, allowing for timely intervention and reduced downtime.

- Adjustable Controllers: Customizable controllers adapt to specific product requirements, optimizing performance.

- Data Analysis Software: Advanced software packages provide detailed insights into product weight data, enabling continuous improvement.

Reduced Costs and Enhanced Quality

Checkweighers offer a multitude of benefits that impact the overall production process:

- Reduced Waste: Checkweighers identify and reject underweight or overweight products, minimizing waste and maximizing product yield.

- Compliance with Regulations: Checkweighers ensure compliance with industry standards and regulatory requirements, protecting your brand reputation.

- Improved Product Quality: Accurate weight measurements foster consistent product quality, meeting consumer expectations.

- Increased Productivity: Efficient checkweighers contribute to a smoother production flow, boosting productivity and reducing downtime.

Maintenance and Support

Regular maintenance is crucial for maintaining optimal checkweigher performance. Many suppliers offer maintenance contracts that provide access to expert technicians and ensure timely repairs.

Choosing the Right Supplier

Partnering with a reputable checkweigher supplier is essential for long-term success. Look for a supplier with a proven track record, offers comprehensive training, and provides ongoing support.

Conclusion

Checkweighers are indispensable tools in the food production industry, ensuring accuracy, efficiency, and product quality. By selecting the right checkweigher and partnering with a reliable supplier, you can optimize your production process, minimize waste, and enhance customer satisfaction.

How can we help?

Contact us to find out how our diverse products, services and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.