We can help with Industrial Marking and Identification Systems information!

What is a checkweigher and why is it important?

A checkweigher is a machine that is used to check the weight of packaged goods. It is typically found at the end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Checkweighers are used in a wide variety of industries, including food and beverage, pharmaceutical, and manufacturing.

Do you struggle with downtime related to Packaging Verification Systems equipment and processes? We will share information and success stories about how you can use Industrial Marking and Identification Systems to focus your energy and efforts on the efficiency of the business. We have insights from industry experts and our partners on the various equipment and technologies available to simplify your challenges.

Solutions and options covered will include:

- Primary package markings

- Secondary package markings

- Primary Barcode Identification

- Secondary Barcode Identification

- Turnkey Solutions for offline printing

- Printer replacements

- Multiple different material marking

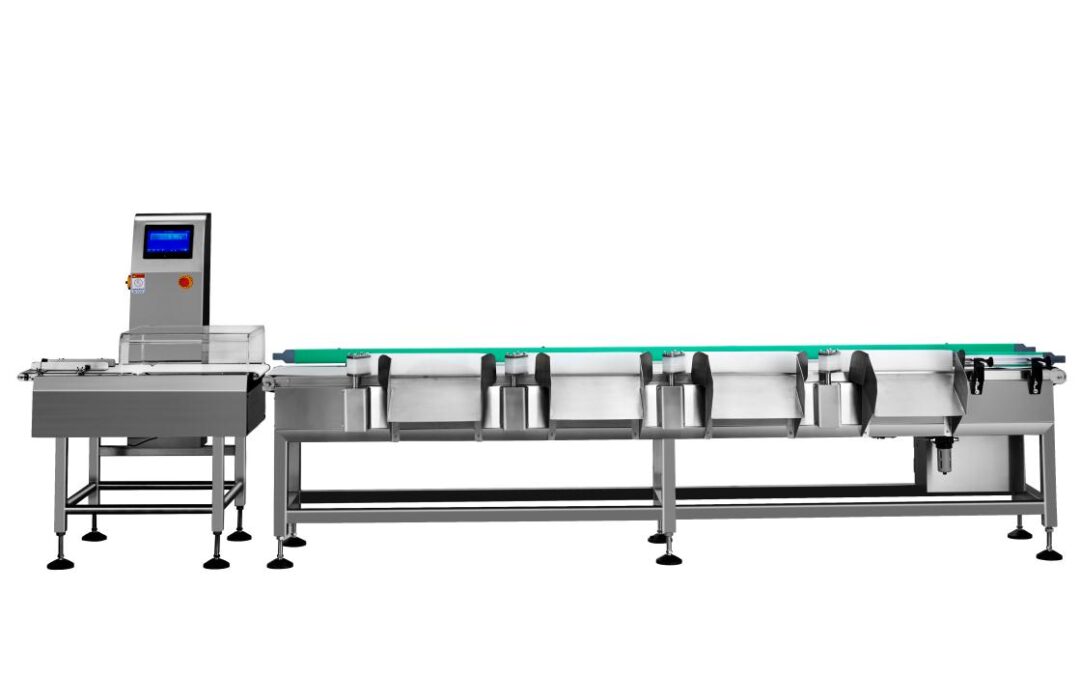

Checkweigher machine

A checkweigher is a machine that is used to check the weight of packaged goods. It is typically found at the end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Checkweighers are used in a wide variety of industries, including food and beverage, pharmaceutical, and manufacturing.

Why is a checkweigher important?

There are several reasons why a checkweigher is important:

- To ensure compliance with regulations: Many industries have regulations that require products to be weighed within certain tolerances. For example, the food and beverage industry has strict regulations regarding the accuracy of product labeling. Checkweighers help to ensure that products meet these regulations.

- To reduce product giveaways: If a product is overweight, the manufacturer is giving away the product. Checkweighers help to reduce product giveaways by identifying and rejecting overweight products.

- To improve product quality: Checkweighers can also be used to improve product quality. For example, a checkweigher can be used to identify products that contain foreign objects. These products can then be rejected before they are shipped to customers.

How does a checkweigher work?

Checkweighers work by weighing products as they move along a conveyor belt. The products are weighed using a load cell, which is a type of sensor that measures weight. The load cell sends a signal to a controller, which compares the weight of the product to the target weight. If the product is within the target weight range, it is allowed to continue on the conveyor belt. If the product is outside of the target weight range, it is rejected.

Different types of checkweighers

There are two main types of checkweighers: static checkweighers and dynamic checkweighers.

- Static checkweighers: Static checkweighers weigh products when they are stationary. This type of checkweigher is typically used for heavier products, such as boxes and bags.

- Dynamic checkweighers: Dynamic checkweighers weigh products while they are moving. This type of checkweigher is typically used for lighter products, such as food packages and pharmaceutical products.

Benefits of using a checkweigher

There are several benefits to using a checkweigher, including:

- Improved product quality: Checkweighers can help to improve product quality by identifying and rejecting products that are outside of the specified weight range.

- Reduced product giveaways: Checkweighers can help reduce product giveaways by identifying and rejecting overweight products.

- Increased compliance: Checkweighers can also help businesses comply with industry regulations regarding the accuracy of product labeling.

- Improved efficiency: Checkweighers can also help to improve production efficiency by identifying and rejecting defective products before they reach the next stage of the production process.

Conclusion

Checkweighers are an important tool for many businesses. They can help to improve product quality, reduce product giveaways, increase compliance, and improve production efficiency. If you are looking for a way to improve your production process, consider investing in a checkweigher.

How can we help?

Contact us to find out how our diverse products, services, and solutions can help your business today.

Contact us for a one-on-one consultation for Packaging Verification Systems or a quote for a new or upgraded Hitachi UX printer. Many options are available. Let us help you find the right one for your business needs.